Adding Pizzazz to Metal Buildings with “Pop-Out” Framing

The most economical shape for pre-engineered steel buildings remains the basic rectangle. While practical for most industrial, agricultural, and storage applications, commercial enterprises sometime require more visual interest.

In this series on customizing steel buildings, we have divulged several ways to lose the “boxy” look of metal buildings to add eye appeal. So far, we have covered:

In this series on customizing steel buildings, we have divulged several ways to lose the “boxy” look of metal buildings to add eye appeal. So far, we have covered:

• Part 1: Changing the Roofline

• Part 2: Adding Roofline Extensions

• Part 3: Using Brick, Stone, Stucco and Other Exterior Building Materials

We can further improve a structure by adding structural “pop-outs,” as another example of a great steel building idea.

Metal Building Basics

First, let’s cover some a couple of basics in pre-engineered steel building construction.

In a clear span steel building, the two steel columns bolted together with two rafter beams create a single “frame. The frames run the length of the structure, much like ribs supporting the skeleton of the building.

In a clear span steel building, the two steel columns bolted together with two rafter beams create a single “frame. The frames run the length of the structure, much like ribs supporting the skeleton of the building.

Typically, frames are spaced 20’-25’ apart. The distance between the frames is called a “bay.”

The frames continue for the length of the structure, creating the basic rectangle of the building.

So What is a “Pop-out”?

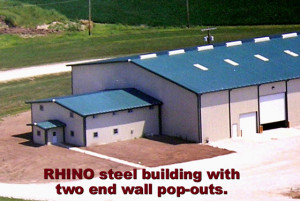

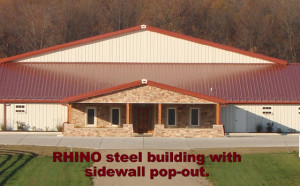

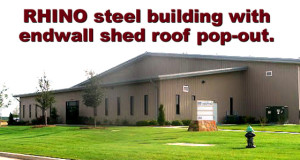

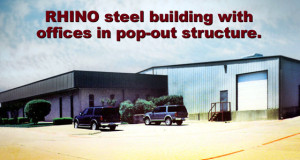

Adding smaller frames outside the main structure creates pop-outs. This adds square footage to the structure while breaking up the rectangular shape of the building. Pop-outs can be added at either the end wall or sidewall.

Adding smaller frames outside the main structure creates pop-outs. This adds square footage to the structure while breaking up the rectangular shape of the building. Pop-outs can be added at either the end wall or sidewall.

Pop-outs offer many practical uses.

For example, a pop-out section on a church, hotel, medical building, school, or nursing home could create a protected drop-off porte cochére. Warehouses and manufacturing plants with towering ceilings might use a lower ceiling pop-out for offices. Hospital, hotels, and business offices often add a pop-out for lobby space or an eye-catching foyer.

When Is a Pop-out Practical?

There are several considerations when planning a building with pop-outs.

- The size and configuration of the building lot must accommodate the added pop-outs.

- Pop-outs must be shorter than the main structure.

- Although the pop-out can be the same width as the main structure, a smaller width offers more visual contrast.

- In northern climates with heavy snow, pop-outs must be engineered to withstand the additional weight.

- End wall pop-outs should not be used if future expansion is a possibility.

Thinking Outside the Box Creates Amazing Steel Buildings

Call one of RHINO’s experienced steel building specialists today to discuss your metal building project. They will discuss all the ways to “dress up” a steel building to meet your building criteria. They know the most economical configurations to meet your expectations— and your budget.

Call one of RHINO’s experienced steel building specialists today to discuss your metal building project. They will discuss all the ways to “dress up” a steel building to meet your building criteria. They know the most economical configurations to meet your expectations— and your budget.

The RHINO number is 940.383.9566. Get started on your dream building project today and get more steel building ideas with RHINO.