When Building Green, the Best Deal is Steel

As in any other construction enterprise today, green building matters to an auto dealership. In fact, eco-friendly construction matters to all vehicle dealerships, whether for cars, boats, recreational vehicles, motorcycles, trucks, or tractors and farm equipment.

Where do you start? Green building begins with steel.

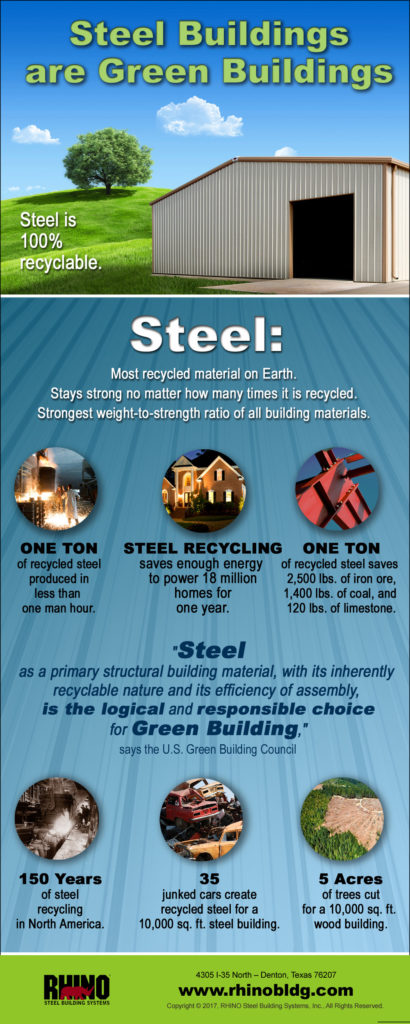

Steel: The Most Recycled Material on Earth

Steel: The Most Recycled Material on Earth

No other material on the planet comes close to matching the recycling record of steel.

The steel industry is no Johnny-come-lately to recycling; the North American steel industry has been recycling steel scrap for over 150 years.

Steel scrap is the main ingredient in all new steel. Modern furnaces are created to consume steel scrap.

Why was steel so far ahead of other industries in jumping on the recycling bandwagon?

Steel has two characteristics that make recycling fiscally feasible.

First, it is economical handle. Steel’s magnetic qualities allow scrap to be separated and moved easily through the use if huge electromagnets.

Secondly, steel is the only material to retain all its strength when recycled. No matter how many times the same steel recycles into new automobiles, steel cans, railroad car, ships, refrigerators— or even new buildings— it never losses any strength.

Every ton of steel produced with recycled metal scrap cuts mining waste by 97%— and reduces production pollution by 86%.

Pre-engineered Steel Buildings Cut Waste

Construction and demolition (C&D) waste fills our nation’s overcrowded landfills. These building materials include asphalt, concrete, drywall, lumber, glass, plastics, and “green” debris like trees, rocks, and stumps.

The Environmental Protection Agency (EPA) estimates 60% of all construction and demolition debris winds up in landfills. Parts of these materials are toxic and considered hazardous waste.

Pre-engineered steel buildings reduce waste three ways:

- Metal buildings deliver prefabricated parts. The framing pieces arrive already cut to length, welded into shape, and drilled for bolting. There is practically no steel waste at the end of construction.

- There is no need to dump any steel framing into landfills. Discarded steel is sold to the local scrap metal dealer. This is true both in the construction of the building and the demolition of a steel structure.

- Steel-framed buildings last decades longer than other building systems, reducing construction and demolition (C&D) volume.

Dealerships Built with Steel Save Energy

Rigid steel framing creates an extra-deep wall cavity, leaving room for thicker insulation.

RHINO Steel Building Systems’ Pro-Value insulation significantly reduces energy expenditure, saving up to 50% over other building systems.

Pre-engineered metal buildings go up straight— and stay that way throughout the life of the structure. There is no shifting, creeping, or loosening in a pre-engineered steel building. Windows and doors continue to shut tightly. Steel buildings avoid the air leaks and draftiness common in aging lumber- framed structures.

Pre-engineered metal buildings go up straight— and stay that way throughout the life of the structure. There is no shifting, creeping, or loosening in a pre-engineered steel building. Windows and doors continue to shut tightly. Steel buildings avoid the air leaks and draftiness common in aging lumber- framed structures.

The steel recycling process itself saves energy, too. Every ton of recycled steel saves 10.9 million Btu’s of energy, 1.8 barrels of oil, and four cubic yards of landfill space.

Environmental agencies recognize steel as the greenest building material, based largely on its high-recycled content. The U.S. Green Building Council calls steel framing “the logical and responsible choice for Green Building.” The LEED (Leadership for Energy & Environmental Design) awards steel an automatic minimum default on its point system— the only building material so rated.

Steel Buildings Avoid Chemical Treatments

Wood attracts and feeds termites, wood ants, mice, rats, mold and mildew. Consequently, lumber must be treated with heavy-duty chemicals to discourage pests and fungi infestations. A wood-framed structure and the ground surrounding it require expensive insecticide treatments on a regular basis.

Steel never supports termites, vermin, mildew, or mold. No chemical treatments are necessary!

Building with Steel Saves Trees

You cannot be a serious environmentalist without loving trees.

Trees inhale carbon dioxide from the atmosphere and exhale life-giving oxygen. The more trees alive and well, the better off we all will breathe.

You can construct a 20,000 sq. ft. green auto dealership with the wood cut from five acres of forest— or with the steel reclaimed from 60 or 80 junked cars. That’s a no-brainer.

Building Green Auto Dealerships with RHINO

Building green auto dealerships becomes easy with a RHINO rigid red-iron steel building

Discuss RHINO green metal buildings for an auto dealership, boat showroom, motorcycle sales office, RV and camper dealership, or a tractor and farm equipment showroom. Speak to a helpful and friendly RHINO steel building specialists by calling 940.383.9566.

Call RHINO today for a free quote and the best deal in steel.