Steel: The Environmentally Sound Choice for Chopper Hangars

Astute aircraft owners choose to build green helicopter hangars with steel. Chopper businesses and recreational enthusiasts alike appreciate the environmental benefits afforded by steel construction.

An Arial Perspective on the Planet

An Arial Perspective on the Planet

Hovering high over our incredible planet offers chopper pilots and crews a unique view of Earth’s beauty— and its struggles. Along with breathtaking natural vistas, they also see man’s marks on the land: clouds of pollution, urban sprawl, decimated forests, overflowing landfills, and rivers choked with debris.

Such a perspective gives helo crews a heart for the land— and a deep desire to help alleviate mankind’s scars on it. When constructing hangars to house their choppers, environmental responsibility ranks high on their list of priorities:

• As pilots, they demand strong, durable structures to protect their aircraft.

• As proprietors, they expect a sound investment at an affordable price.

• As people residing on this planet, they chose eco-friendly building materials.

Pre-engineered steel hangars meet all these criteria.

Steel Hangars are Green Helicopter Hangars

Pre-engineered metal chopper hangars promise many advantages, including eco-friendly, green construction materials. Building metal helicopter hangars with steel delivers the best deal for our planet, the owner’s pocketbook, and for the pilot and crew’s peace of mind. Here is why:

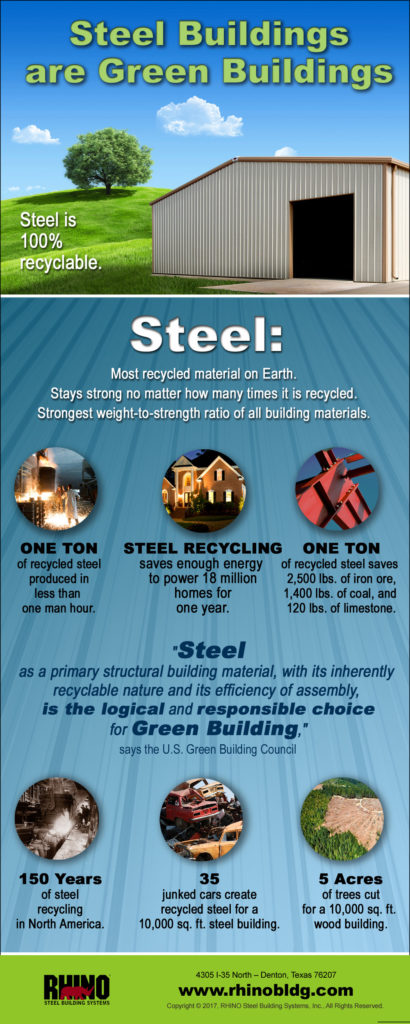

RECYCLED: No material on our planet matches the recycling record of steel.

One hundred percent recyclable, steel never loses any of its characteristic strength— no matter how many times it is recycled.

All steel now contains recycled steel. North American iron and steel makers started recycling over 150 years ago.

Only one building material in the LEED (Leadership in Energy & Environmental Design) green building program boasts an automatic minimum: steel.

HEALTHIER: Every hangar or structure built with steel instead of wood means more living trees in the forests of our planet. Trees remove airborne contaminants, replacing our atmosphere with life-giving oxygen.

Consider this:

Harvesting five acres of forest produces enough lumber to construct a 10,000 sq. ft. structure. Preserving that same five acres of forest allows as much as 1.5 tons of air pollutants to be processed each year by those same trees, cleaning the air we all breathe. The same 10,000 sq. ft. structure can be constructed with the recycled steel garnered from about 35 scrapped cars.

Untreated wood hangars attract termites. Lumber treated with toxic chemicals repels termites, but outgasses into the air, contaminating the air for pilots and crewmembers. (These chemicals also leech into the ground and water table, further polluting our environment.)

Termites cannot chew on steel framing. Steel never outgasses. In addition, inorganic steel never supports mold growth or rot, like wood hangars and buildings.

STRENGTH: No other building material matches the strength-to-weight ratio of steel.

PERFORMANCE: Pre-engineered steel hangars and buildings last decades longer than other hangars. The longer it lasts, the less the impact a structure makes on the environment.

REDUCED WASTE: Steel’s reliability and consistency allow engineers to create incredibly strong hangars with the least possible material.

Need proof? Wood structures frame with exterior studs placed 16 inches apart. Pre-engineered steel buildings insert steel columns every 25 feet apart.

Since all the building components arrive ready to assemble, pre-engineered metal helicopter hangars waste little material or time.

At the end of the hangar’s lifecycle, the steel lives on, recycled once more into aircraft parts, automobiles and trucks, cans, bridges, large appliances, ships and submarines, trains— or possibly another eco-friendly aircraft hangar.

FIRE: Hangar fires spread quickly in wood structures, as the lumber provides more fuel for the blaze. Steel is non-combustible. It never adds fuel to a fire.

FIRE: Hangar fires spread quickly in wood structures, as the lumber provides more fuel for the blaze. Steel is non-combustible. It never adds fuel to a fire.

Lightning, another fire hazard, is more likely to damage wood hangars than metal structures. In a well-grounded steel hangar, lightning passes directly into the ground.

Most insurance companies give big discounts to steel hangar owners, chiefly because of steel’s non-combustible nature.

Building Green Hangars with RHINO

Build green helicopter hangars with RHINO Steel Building Systems. Help conserve natural resources and save lovely, green money, too. That’s a win/win proposition for all chopper owners. Climate-controlled hangars using the RHINO Pro-Value insulating system slash energy costs by 50%, saving even more money.

Do you want more details about green helicopter hangar construction materials for your whirlybirds, gliders, or other aircraft? Call RHINO today! Speak to a RHINO metal hangar specialist at 940.383.9566.

We will be happy to help you with a free quote and design tips for your next hangar, shade shelter, or aircraft support structure.