Tips for Planning Steel Buildings for Extreme Winters

There are many considerations when planning metal buildings for snow country. Preparing for extreme snow and ice conditions begins with effective planning before your pre-engineered metal building is ordered.

Locating the building site

The first consideration is placement of the structure on your site.

Prevailing winds greatly affect snow buildup on and around a structure. The winds shift the snow, creating drifts on the roof of a building.

Prevailing winds greatly affect snow buildup on and around a structure. The winds shift the snow, creating drifts on the roof of a building.

Configuring a structure with the roof’s main ridgeline perpendicular to the prevailing winds causes snow to sweep across the windward side and pile deeply on the leeward side of the building. Snow distributed unevenly across a roof places greater stress on the structure. Building the structure with the ridgeway pointed toward the prevailing winds helps prevent the uneven accumulation of snow on the roof.

Tall evergreen trees on the windward side of a building help create a windbreak. Windbreaks not only reduce the amount of snow accumulated on the roof, but also help block icy winds, helping to keep the structure warmer.

Keep the roofline simple

The most effective building design for snow country is a straight, single- ridge gable roof. Simple gable roofs shed snow and ice more quickly than complicated rooflines. Roofs with valleys, dormers, and other obstructions causes snow on metal roofs to building up erratically.

The slope of the roof is also extremely important. Too shallow a slope causes snow on metal roofs to stay there longer, increasing the strain on the structure. Too high a slope may create a hazardous situation when great amounts of snow or ice slide off all at once.

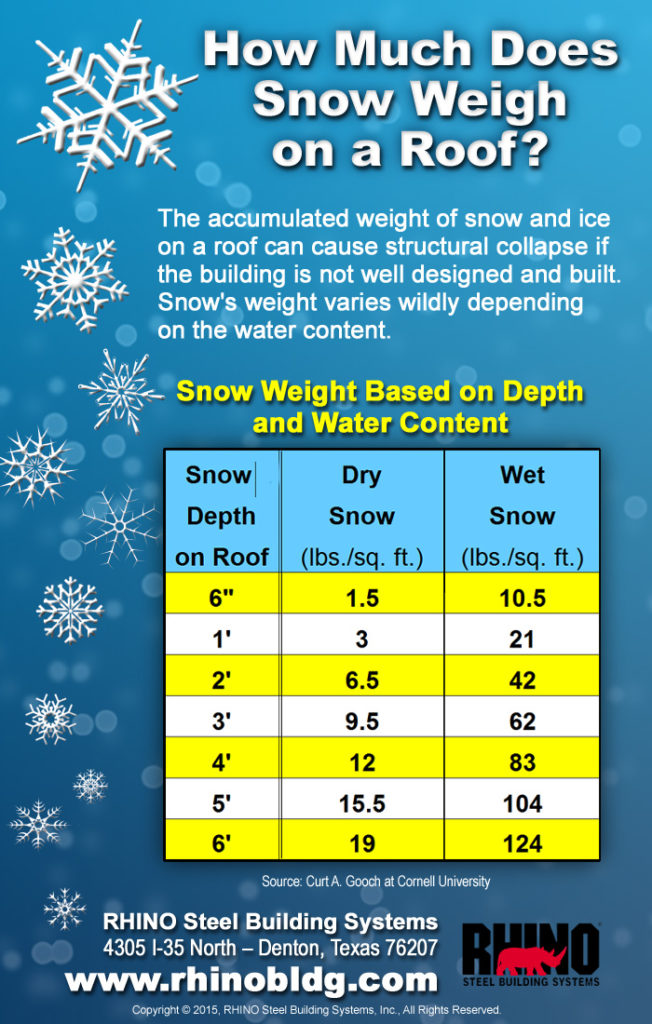

Sliding snow and ice actually wrecks more havoc— and results in more damage— than excessive snow piled on the roof. Snow can weigh 30 pounds-per-cubic-foot or more. If your roof has accumulated three feet of snow, that’s 90 pounds-per-square foot— or more.

In the Sierra Nevada Mountains snow, loads are the most extreme in the U.S. The moisture coming in from the Pacific Ocean makes snow in this region extremely heavy. Locals call it “Sierra Cement.” In the Lake Tahoe area, for example, ground snow loads may reach 450 pounds-per-square foot! Refer to the roof snow load chart below to see how much snow can weigh on your roof.

Sliding snow often shears off chimneys, vents, and other roof obstructions. Massive snow suddenly sliding off a roof sometimes kills the unsuspecting caught below it.

Roof pitches of 3:12, 4:12, 5:12, or 6:12 work best for metal buildings in snow country. Anything over a 6:12 pitch tends to make massive amounts of snow slide off the roof without warning. Anything less than 1:12 pitch is a huge mistake in snow-prone climates. Standing seam metal roofs— which allow snow to slide more easily— might do better with a 2:12 or 3:12 pitch.

The ideal location for an entrance is on the endwall under the gable. Designing the entrance on the opposite end of the prevailing wind is preferable.

Metal buildings usually do not have eave overhangs. In some locations, builders prefer overhangs to prevent snow on metal roofs from sliding off the roof and down the side of the building. However, unheated overhangs on a heated building increase the likelihood of damaging ice dams. Discuss the pros and cons of overhangs with your metal building supplier and with your local building department.

Metal buildings usually do not have eave overhangs. In some locations, builders prefer overhangs to prevent snow on metal roofs from sliding off the roof and down the side of the building. However, unheated overhangs on a heated building increase the likelihood of damaging ice dams. Discuss the pros and cons of overhangs with your metal building supplier and with your local building department.

Gutters in snow country

Gutters and downspouts move water from melting snow and ice away from the structure. However, if the gutters are not properly maintained and cleaned, they can also block water’s exit. In poorly draining gutters, water refreezes as temperatures plummet, forming a backup that leads to ice dams. Some building owners resort to heat cables in gutters to avoid refreezing.

Heavy sliding snow and ice sometimes rip gutters and downspouts from the structure.

Discuss the winter weather in your location with your metal building supplier and your local building department for advice on including— or excluding— gutters and downspouts for your location.

Insulating metal buildings for snow country

Buildings in snow country need adequate insulation to withstand tough winters. Because steel building walls are much deeper than wood-framed structures, metal buildings allow room for thicker, more energy efficient insulation.

Additional design tips for metal buildings in snow country include:

- Cover entrances to protect from the weather.

- Place the majority of windows on the south-facing wall. Put as few windows on the north-facing walls as possible.

- Avoid the use of skylights.

- Chimneys are best located on the ridgeline for maximum support.

RHINO steel buildings in snow country

The metal buildings available from RHINO Steel Building Systems offer unparalleled benefits in snow country:

- RHINO steel buildings are guaranteed to meet or exceed all snow loads and building codes for which the building was designed— for the lifetime of the structure.

- RHINO’s Pro-Value ultra-thick insulation packages provide excellent energy efficiency for even the coldest climates. The Pro-Value Insulation is not just thicker insulation. It is an insulation system, including steel retaining straps, a durable fabric vapor barrier, a thermal break material, and thick fiberglass insulation up to R-38.

- Made of high-grade 26-gauge steel, RHINO’s gutters and downspouts are deeper throated to move water faster. Available in colors to match any building, these big gutters act as trim on the structures. Over 60% of RHINO customers choose to add gutters and downspouts to their steel building orders. (However, gutters and downspouts are not recommended in extreme snowfall areas.)

- RHINO ships steel buildings all across North America, including Canada and Mexico.

Learn more about designing metal buildings for snow country by calling RHINO Steel Building Systems today at 940.383.9566.