Why Steel Reigns as the King of Green Building

Recycled steel continues to reign supreme as the king of all recycled materials.

This year marks the thirtieth anniversary of the Steel Recycling Institute. Consequently, now seems like the perfect time to review the impressive record of steel recycling in the U.S.

Steel’s Recycling Edge

Three attributes of steel give it an edge over other recycled materials.

Three attributes of steel give it an edge over other recycled materials.

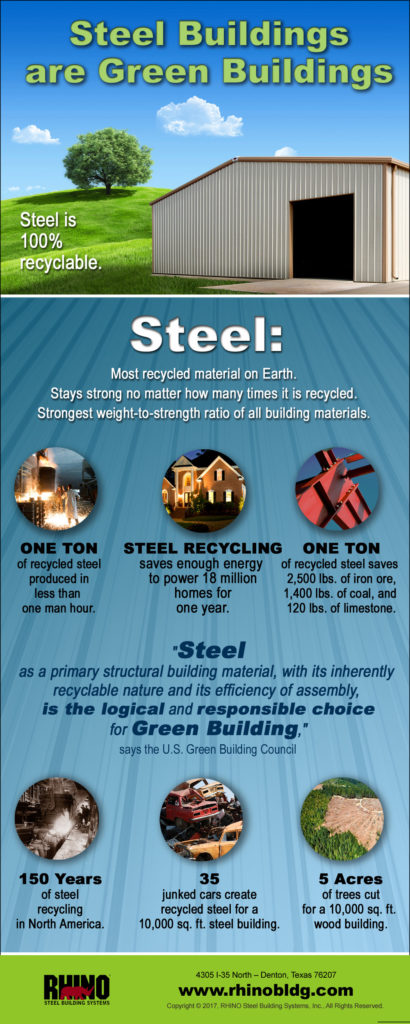

First of all, recycling steel does not change its strength. No matter how many times steel is recycled, it remains just as strong as when it was first produced. No other recycled material can make that claim.

Secondly, handling discarded steel costs less than sorting and processing other recyclables. Steel’s magnetic qualities make it simple to separate from other debris. Huge electro magnets easily pull steel from other castoffs.

Thirdly, products made of steel last longer. Steel buildings, for example, outlast wood structures by decades.

The Environmental Predicament: Profit vs. Planet

Simple economics make recycling steel the smart choice. Steel production remains a business. As it does in any commercial business, the bottom line influences every decision. And the bottom line in steel production is this:

It costs far less to create recycled steel than to produce virgin steel.

Every ton of recycled steel produced saves:

- 9 million Btu’s of energy

- 2,500 pounds of iron ore

- 1,400 pounds of coal

- 250 cubic feet of landfill space

- 642 kWh of electricity

- 120 pounds of limestone

- 76 gallons of oil

No wonder North American steel producers have been recycling steel for over 170 years!

Fortunately, this is one of those rare instances when what is good for profitability is also good for the planet.

Recycled Steel: The Green Champion

Just look at these mind-boggling steel recycling statistics:

Just look at these mind-boggling steel recycling statistics:

- Over 80 million tons of steel is recycled in North America each year.

- All steel products sold today contain at least 28% recycled steel.

- Recycling steel saves enough energy annually to power 18 million households for a full year!

- Over 12 million scrapped cars are recycled each year in the U.S.

- Steel producers recycle 95% of all the water needed for steel processing.

- American steel producers cut air emissions 90% in the past decade.

- Today one ton of steel can be created in less than two man-hours.

- The steel recycled from 50 to 60 scrapped autos can produce the metal framing for a 20,000 sq. ft. commercial steel building. A wood-framed building that size would consume 10 acres or more of forest. Those same wooded 10 acres produce enough oxygen for 180 people to breathe for a year.

- Today’s new steel takes 75% less energy to produce and is 30% stronger than the steel produced in the last century.

- About 600 steel cans are recycled every second. The 20 billion steel cans recycled last year would create a path to the moon and back— seven times!

Going Green with RHINO Steel Buildings

RHINO Steel Building Systems offers additional green benefits for the environmentally conscious builder: Our structures include the following eco-friendly features:

- RHINO’s Pro-Value Insulation Package cuts a building’s energy consumption in half.

- In hot climates, RHINO’s reflective paint steel roof panels reduce energy consumption another 7% to 15%.

- RHINO ships building kits from the nearest of multiple shipping points, further reducing energy consumption and freight costs.

Start your next green building project with RHINO. Call us today at 940.383.9566 for complete information and a fast, friendly steel building estimate.